GreenTech approached Universal Leaf with the idea of assessing their external lighting at their 1.2 million square-foot plant in Nashville, NC. Illuminating the area was not only consuming vast amounts of energy, but was also becoming an operational issue as many of the lamps and ballasts were becoming dated. Many of the pole lights, flood lights, and street lights were becoming dirty and worn. Delivery trucks and cars come through these areas daily, and safety and security was becoming a concern with the low visibility demonstrated by the current lighting technology. The existing count was as follows:

- 30 250W Ceramic MH

- 32 400W Ceramic MH

- 22 750W Ceramic MH

- 69 1000W Ceramic MH

In the initial assessment, GreenTech noticed that the challenge was going to be meeting the high lumen output flood lights and parking lot lights that took up the majority of the area. While most of the pole lights, floods, and wall packs were old and degraded, all of the wall wash lights were fairly new and in good condition. This led GreenTech to recommend a combination of new fixtures and retrofits as a solution to minimize cost of ownership, reduce energy consumption, and improve light levels.

For the 250W wallpacks located on the detached buildings, GreenTech recommended replacing these with 75W LED wallpacks. This not only reduced operational costs, but provided for a consistent color of light to areas that were characterized by multiple colors (cool & warm). The same could be said for the 400W wall washers that were located around the main facility. These fixtures, however, were in good condition, so GreenTech decided to retrofit these fixtures with 120W LED retrofit kits. The end result was a consistent color and lumen output that beautified the surrounding areas and provided for greater security.

For the 750W street lights GreenTech converted these to new 200W LED fixtures and the 1000W parking lot lights were converted to an exclusive 300W fixture that both carried the same 5000k color to provide for increased pupil lumens for driver safety and security. The 1000W flood lights were replaced with state-of-the-art 280W fixtures that carry a 32,000 lumen output to increase visual lighting in the docking stations. This combination translated into 73% in lighting energy savings and the average 50,000 hour lifecycle reduced the frequency for hiring electricians and lift rentals to continually replace the lamps and ballasts as they went out.

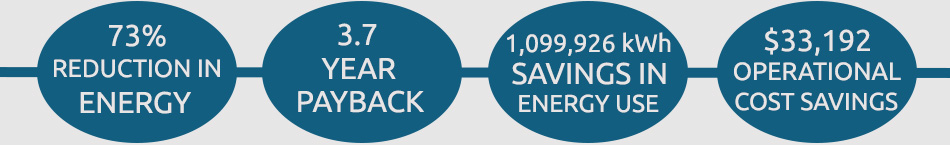

As a result, GreenTech was able to deliver a solution that not only helped reduce lighting energy usage and operational costs, but was able to increase lumen output to maximize safety and provide for a uniform color consistency throughout the area. Although Universal Leaf opted out of the Duke Energy Rebate program due to heavy manufacturing energy usage and the facility operating at only 9 months out of the year, the following benefits were experienced:

- 73% reduction of lighting energy usage

- 3.7 year payback

- 100% reduction in maintenance costs

- 256,200W projected annual watts savings

- $33,192 annual operational cost savings

Due to the success of the project Universal Leaf has contracted GreenTech to install LEDs in the offices and the manufacturing plants to help further their energy efficient lighting plans. Stay tuned for updates on this project!

LINKEDIN

LINKEDIN